Hot key words:Brake drum Hub Brake pads

CONTACT:

Manager Lv:0086-13831914368ADDRESS:

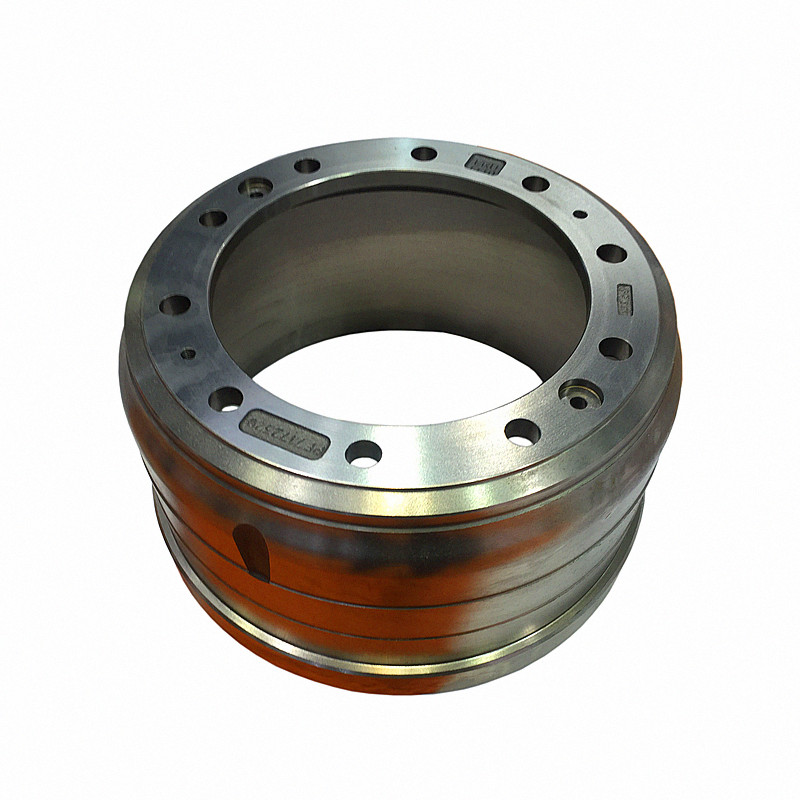

No. 12, A3, gucheng industrial park, longyao county, xingtai city, hebei province.The basic shape of the brake drum is drum, and there is a connecting hole on the mounting surface.

According to the different manufacturing methods, the structure of the brake drum mainly has the following three kinds:

1. Integral casting type

Brake drum is made of high strength gray cast iron or alloy cast iron containing Cr. This kind of brake drum has simple structure, convenient processing, large heat capacity, but large mass, and is mostly used for medium and heavy duty vehicles.

2. Combined steel plate and cast iron

Brake drum by steel plate stamping drum and cast iron drum ring two parts of a body, the mass is small, used for cars and light vehicles.

3. Combination of light alloy and cast iron

Brake drum body is light alloy material (such as aluminum alloy, etc.), lined with cast iron lining ring. This kind of brake drum is not only of small quality, but also of good heat dissipation. It is mostly used for cars.

Cause analysis of automobile brake drum failure

1. Cause analysis of cracking failure

Automobile brake drum will be affected by various forces in the process of conventional operation, mainly including the normal pressure and rotation of the shoe and the tangential force of the clutch of the shoe. The two forces complement each other. If the normal pressure is absent, the tangential force will disappear. However, in the normal operation process, there will be friction and heat between the two, at this time the temperature of the brake drum will continue to rise, and the friction between the two is spotty contact friction, so the contact surface will also be heated by friction, and phase transition stress will eventually occur. The phase change stress will lead to uneven force on the brake drum, and regular cracks will occur in the brake drum under the frequent brake load.

2. Cracking failure cause analysis

Brake drum cracking also covers two levels of cause. First of all, the brake drum will be affected by the material strength difference, resulting in cracking problem. Secondly, after the brake drum cracking problem occurs, the brake drum will also produce local phase transformation under the interaction of thermal stress and phase transformation reaction, resulting in the reduction of strength. At this time, cracks on the brake surface will continue to expand, leading to the occurrence of cracking.

3. Bottom drop failure cause analysis

In the automobile brake drum without cracking under the premise of direct cracking, this is the bottom failure, it will lead to the direct failure of the brake drum. Specifically, it also includes two points: first, the brake drum material strength is not good, and secondly, under the action of some unreasonable abnormal external forces, the brake drum will crack indirectly because the flange layer is affected by torsional force. At this time, the brake drum flange layer will crack and crack, and finally cause the bottom problem.

4. Cause analysis of excessive wear and non-wear failure

Excessive wear and non-wear can easily lead to complete failure of automobile brake drum. First of all, excessive wear means that the working geometric inner diameter and wall thickness of automobile brake drum working belt are getting bigger and bigger under the influence of frequent braking force. It directly has a negative impact on the braking effect of the brake drum. Look at the abnormal wear failure, when the brake drum working face in the shoe and other hard object external force S, due to friction contact will appear groove, it is often caused by unreasonable riveting friction sheet, to a certain extent is also due to the insufficient hardness of the brake drum caused by.